08.04.2025

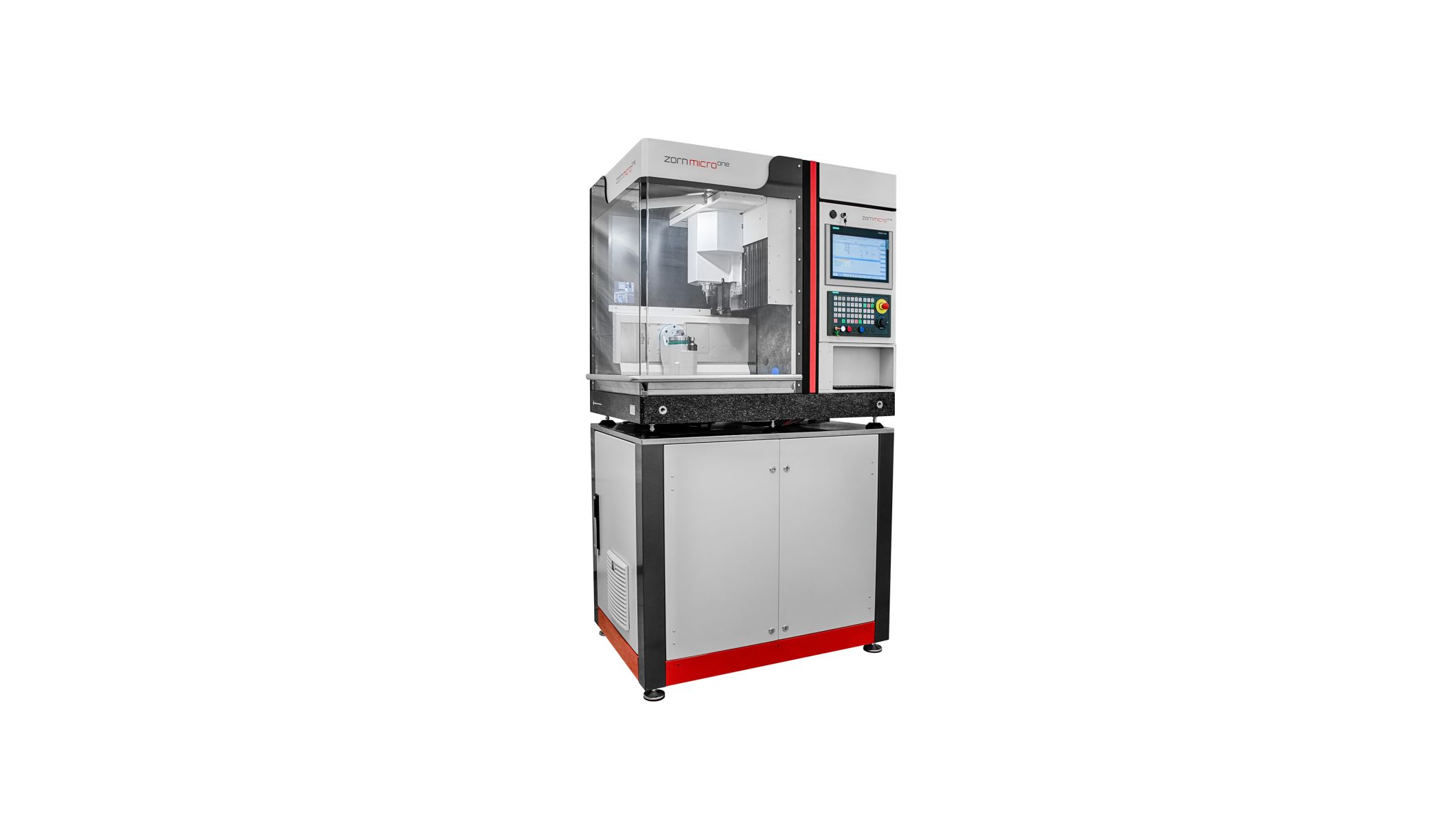

Visit us at EPHJ 2025 and discover our proven solutions in micromachining and the watch industry. Our technologies offer decisive advantages for the watch and jewelry industry, as well as medical technology, enabling maximum efficiency and precision in your production.