Markforged – Industrial quality, at an affordable price

Composite and metal 3D printer

Markforged, a company headquartered in the USA, has been manufacturing high-performance 3D printers for various materials – such as nylon, chopped carbon fiber, reinforcing continuous filament and metal – since 2013.

Composite refers to a composite material made of plastic reinforced with short or continuous fibers – such as carbon. Printed composite parts meet the high requirements in terms of strength, rigidity, precision and durability, and can, therefore, even replace aluminum parts. With the additional “FX10 Metal Kit”, Markforged also enables the production of metal components from the 3D printer.

Pre-processing and design:

Create and import print data

In order to create a digital template, the data must first be prepared. Such a 3D model can be designed using a CAD program, or digitized using a 3D scanner. This is followed by checking the CAD model, correct positioning on the respective surface and adding support structures.

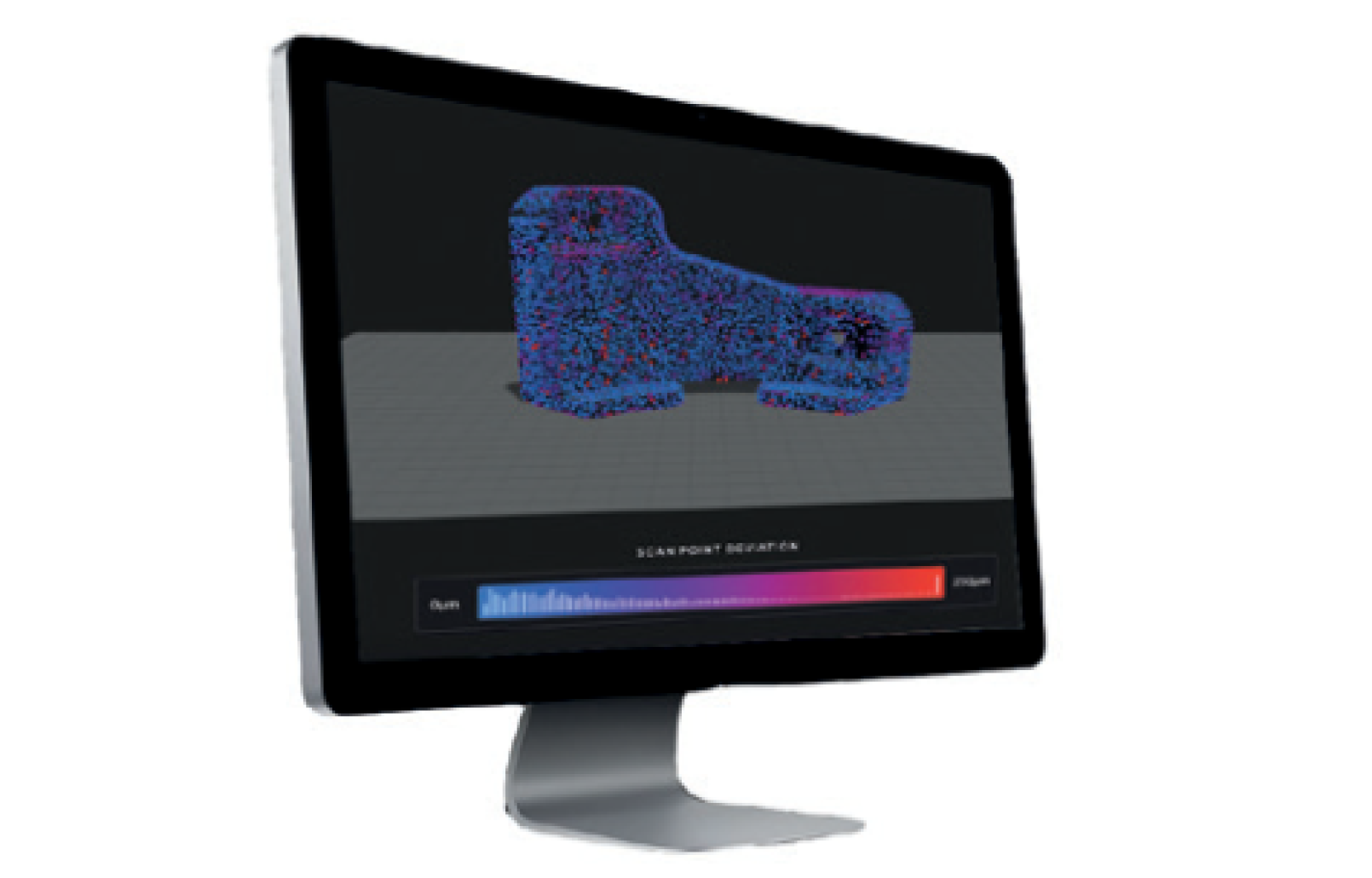

3D scan

Easily measure objects with the portable “Handy Scan 3D” from Creaform, in order to obtain the component’s CAD data, or subject components to a subsequent quality check by scanning the finished workpiece.

Software

The multifunctional software "Eiger" from Markforged offers a wide range of options – from the creation of parts to their management in additive manufacturing workflows. Thanks to the cloud connection, additive manufacturing in tomorrow’s world is possible anytime and anywhere with seamless access on demand.

Production:

3D printing from composite and metal

Using a composite printer, the base material is placed in the layer through one nozzle and a continuous fiber through a second nozzle. This results in composite parts components with very high strength, which can even replace conventionally manufactured aluminum parts. With the additionally available “FX10 Metal Kit”, metal components can also be printed.

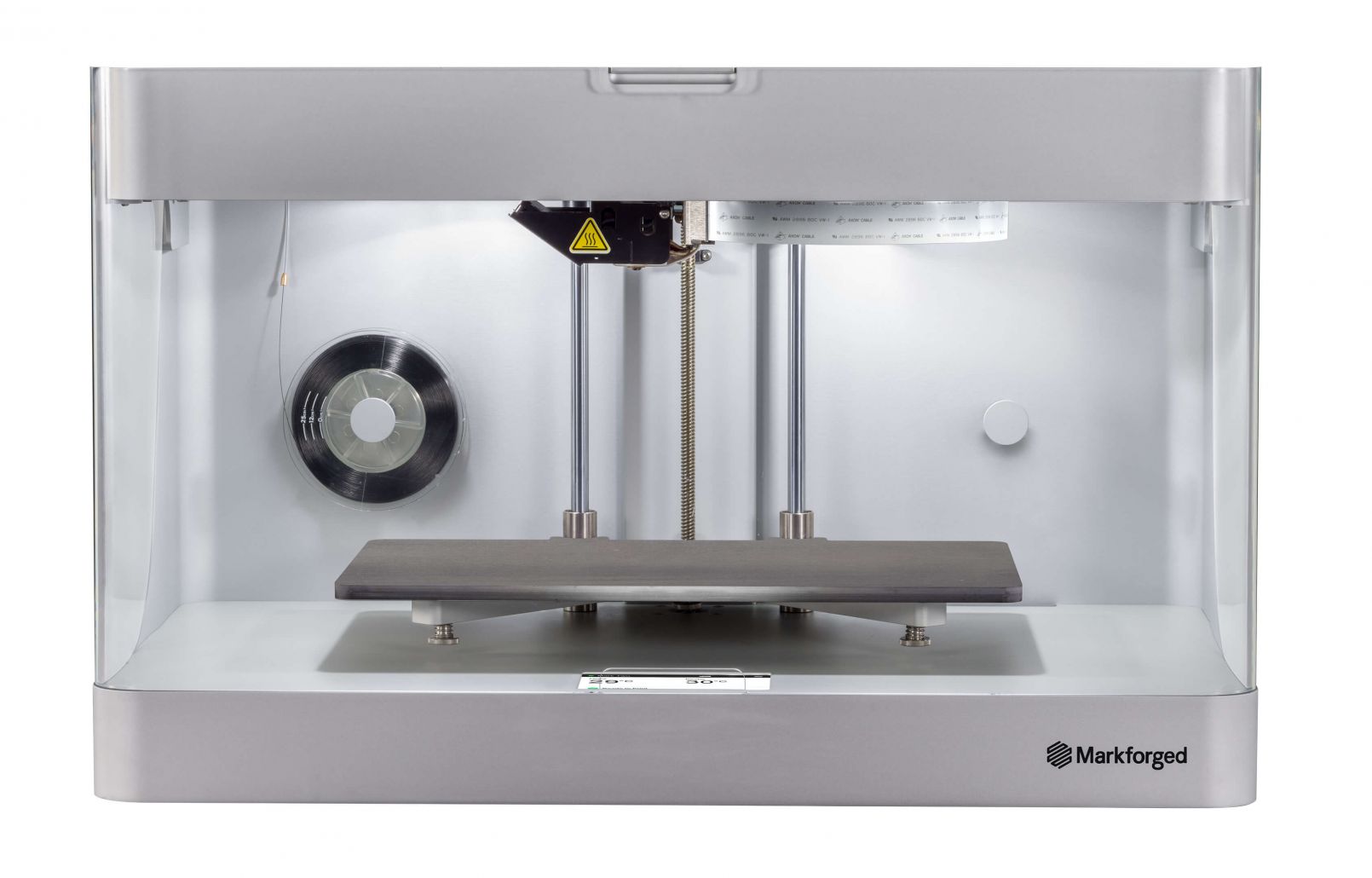

Desktop series

The continuous fiber 3D printer was developed to revolutionize your production methods! This exceptional ability to produce parts with the strength of aluminum right at your workstation – both the Onyx Pro and Markforged’s Mark Two carbon fiber printer make it easy to produce value-enhancing parts for your business.

Industry series

Markforged's Industrial Series 3D printers offer the ability to quickly produce fiber-reinforced carbon parts that are as strong as machined aluminum. The FX10 also offers the option of producing metal parts with an additional “FX10 Metal Kit”.

Printing with composite filaments

The composite printer uses two nozzles that inject both the base material and a continuous fiber into the layer to produce composite parts with exceptional strength that can potentially replace conventional aluminum parts.

“FX10 Metal Kit” - metal parts from a filament printer

With the additional “FX10 Metal Kit”, Markforged also enables the production of metal components from the 3D printer.

FDA and NSF-certified filaments for the food industry

Developed for applications in the food and beverage industry. Nylon White FS is NSF certified to NSF/ANSI Standard 51 and is ideal for applications where the use of a food contact certified material is required or desirable.

Get your free white paper now!

As a competent partner for additive manufacturing, URMA has already demonstrated the potential of up-and-coming 3D printing technology in many exciting applications. We also rely on the proven advantages of additive manufacturing in our own production at our site in the town of Rupperswil. The manufacturing costs of the gripper jaws – which were previously produced using machining processes – have been reduced by a factor of four thanks to 3D printing.

Post-Processing:

Post-processing and quality assurance

The need for post-processing involving 3D-printed parts varies greatly depending on the printing process and the specific requirements relating to the components. URMA offers a variety of solutions and machines for the CNC machining of components.

CNC machining: HAAS

URMA provides a comprehensive selection of vertical and horizontal machining centers, CNC lathes, turning and indexing tables, as well as 5-axis machining centers from HAAS. In addition to this range, URMA also offers machining centers for mold making, machines for tool and fixture construction and milling machines based on a portal design.

CNC machining: Zorn

The Zorn microone is a compact and small precision machining center for milling, drilling and grinding miniature parts in a coordinated motion – including a modular design. The solid granite foundation also absorbs the smallest movements.

URMA – a partner in every respect

URMA is an expert in 3D printing. From initial consultation to quality inspection, we support you in the introduction or expansion of your additive manufacturing. You, too, can benefit from the comprehensive URMA services:

- Consulting

- Services

- Training & Support

- Funding

- System technologies

- Showroom

- Network

- Webshop