May we introduce: Smooth TPU 95A

Reliable 3D printing with elastomer materials

Manufacturers and product developers can now produce rubber-like material properties with the quality, consistency and ease of use of Digital Forge – all with minimal user interaction.

What is Smooth TPU?

TPU (Thermoplastic Polyurethane) is a rubber-like material used to manufacture flexible, shock-absorbing parts. When you think of gaskets, shock absorbers, hoses and drive belts, TPU is one of the few materials used to make these parts.

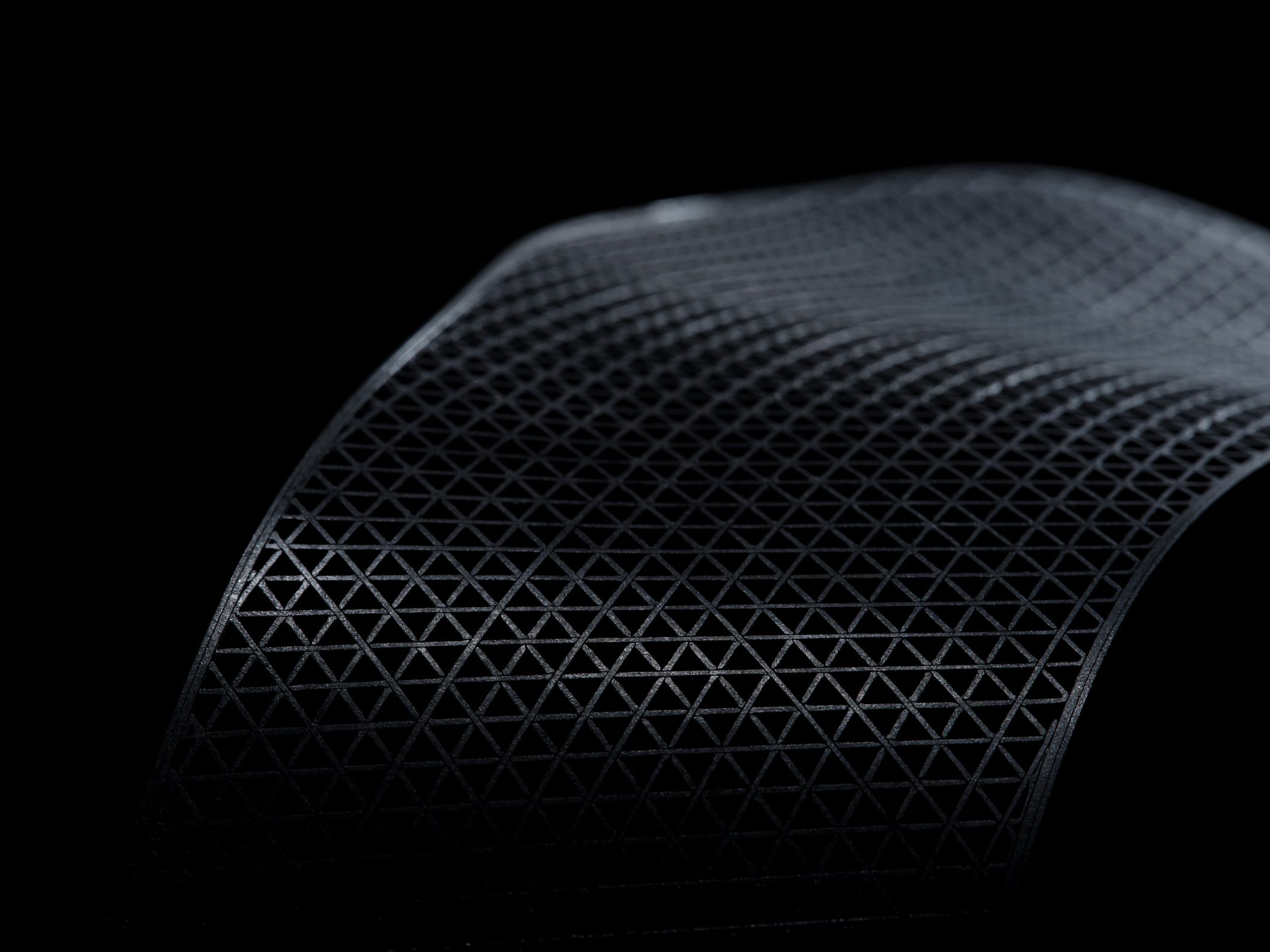

Markforged Smooth TPU is a 3D printing filament that provides the same functionality as conventionally manufactured parts, giving our users the ability to produce custom designs on demand, right where they need to be. It is available in black and white, and can be printed on Mark Two (Gen 2) and Onyx Pro (Gen 2) desktop series printers upon market launch.

Economic advantages of 3D printing of TPU

expensive start-up costs and multi-step processing. Due to the high tooling costs, production with these materials is usually only practical in large quantities. Smooth TPU 95A simplifies the production of flexible, rubber-like parts that are slow and expensive to obtain in small quantities.

With an elongation at break of 500% and a ShoreA hardness of 95, Smooth TPU is suitable as an alternative to conventional production of high-quality, flexible, impact-resistant finished parts below mass production, or for maintaining production lines when older parts are no longer available. Furthermore, for prototyping for design validation before production is ramped up.

Reliable 3D printing with elastomer materials

While the economic advantages of 3D printing TPU are obvious, such filaments are difficult to print in practice. They often cause blockages, clogged systems, and require adjustments to printer settings every time they are printed. After this frustrating preliminary work, the surface quality of a finished part is often very poor and unusable.

You don't need an engineer to optimise print speeds, nozzle temperatures or retract settings – Markforged has done it all for you! While there are several TPU-enabled systems already available for additive manufacturing, few (if any) offer you the same reliability and ease of use as Markforged. As with all Markforged materials, users simply click "Print" and get back to work.

Functionality and versatility of Smooth TPU

SLA and DLP-TPU solutions offer better detail, but these cured resin parts cannot withstand the stresses and strains of real-world applications. Comparable FFF solutions offer similar tensile and elongation properties, but cannot match the accuracy, stability and surface quality of Smooth TPU.

Smooth TPU is the solution that meets both the functional and quality requirements of our customers. And with a matching slicer setting, the flexibility of an 85 ShoreA gasket, 90 ShoreA drive belt or 95 ShoreA shock absorber is mimicked with the same Smooth TPU 95A filament spool.

Now available in our webshop!