Article: URMA AG

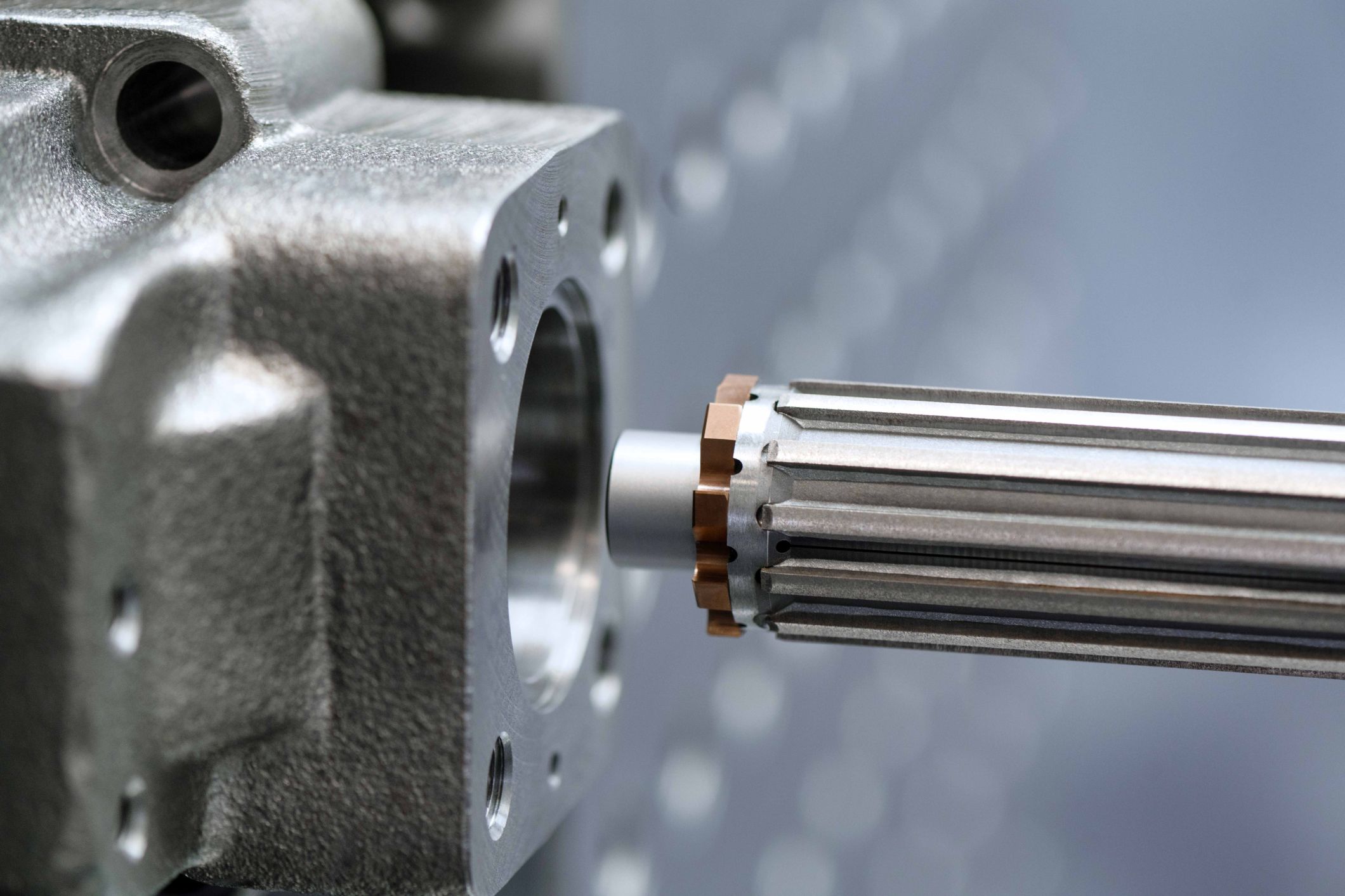

Honing has never been so simple and efficient: URMA AG is expanding its selection of precision tools with the innovative RH reamhone combination tool. With the RH reamhone, URMA AG relies on RX reaming technology, which stands for highest precision and maximum productivity.

PDF: Media release

URMA AG, a company with over 60 years of experience in the manufacture of precision tools, has established itself as a leading expert in the field of precise bore technology. Following the credo "Innovation is our tool", the family-run company, headquartered in Rupperswil, Switzerland, develops and produces innovative precision tool systems. They are used worldwide in industries such as machine builders, the automotive industry, hydraulics and aviation.

Honing requires precise control of the process to ensure consistent surface quality and dimensions. Even small deviations can affect the quality of the final product. The honing process is also time-consuming and cost-intensive, especially for large quantities, complex workpieces and in cases the honing process is outsourced.

The reamhoning tool has been specifically developed for use in milling centers, turning centers or general machining centers. RH reamhone reams and hones bores simultaneously by feeding-in and out in a single work step. Therefore, RH reamhone tools represent an extremely cost-efficient solution for high precision machining in company own production halls, which complies highest tolerance requirements, optimizes production processes and enables automated manufacturing.

RH reamhone offers precise diameter accuracy as well as tight shape and position tolerances and is also suitable for components with multiple journals, such as valve block spool bores.

Advantages of RH reamhone at a glance

Quick-change system for easy handling

Thanks to the precise interface accuracy of <0.004 mm radial run-out, time-consuming adjustment of the run-out is not necessary for the user. The cutting edge can be replaced in less than two minutes, which saves up to 30 minute of downtime compared to other reaming tools.

High friction and honing speed with high feed rate

Thanks to its high feed rate, RH reamhone is ideal for larger quantities and meets the highest requirements for surface quality and precision.

Production of functional surfaces (cross-hatch)

Honing produces precise dimensions and shapes as well as extremely fine surfaces that are smoother than with grinding. The characteristic cross-hatch that occurs during honing and enables a micro-lubricant reservoir that optimizes the tribological properties.

Honing with emulsion or oil

Honing is possible directly on lathes and milling machines without modifying the machine.

Lean production processes

With RH reamhone, the honing process can be integrated directly into the machining process without the need to invest in a honing machine or outsource the honing process.

Process reliability

Innovative tool systems increase process reliability and contribute to increased efficiency.