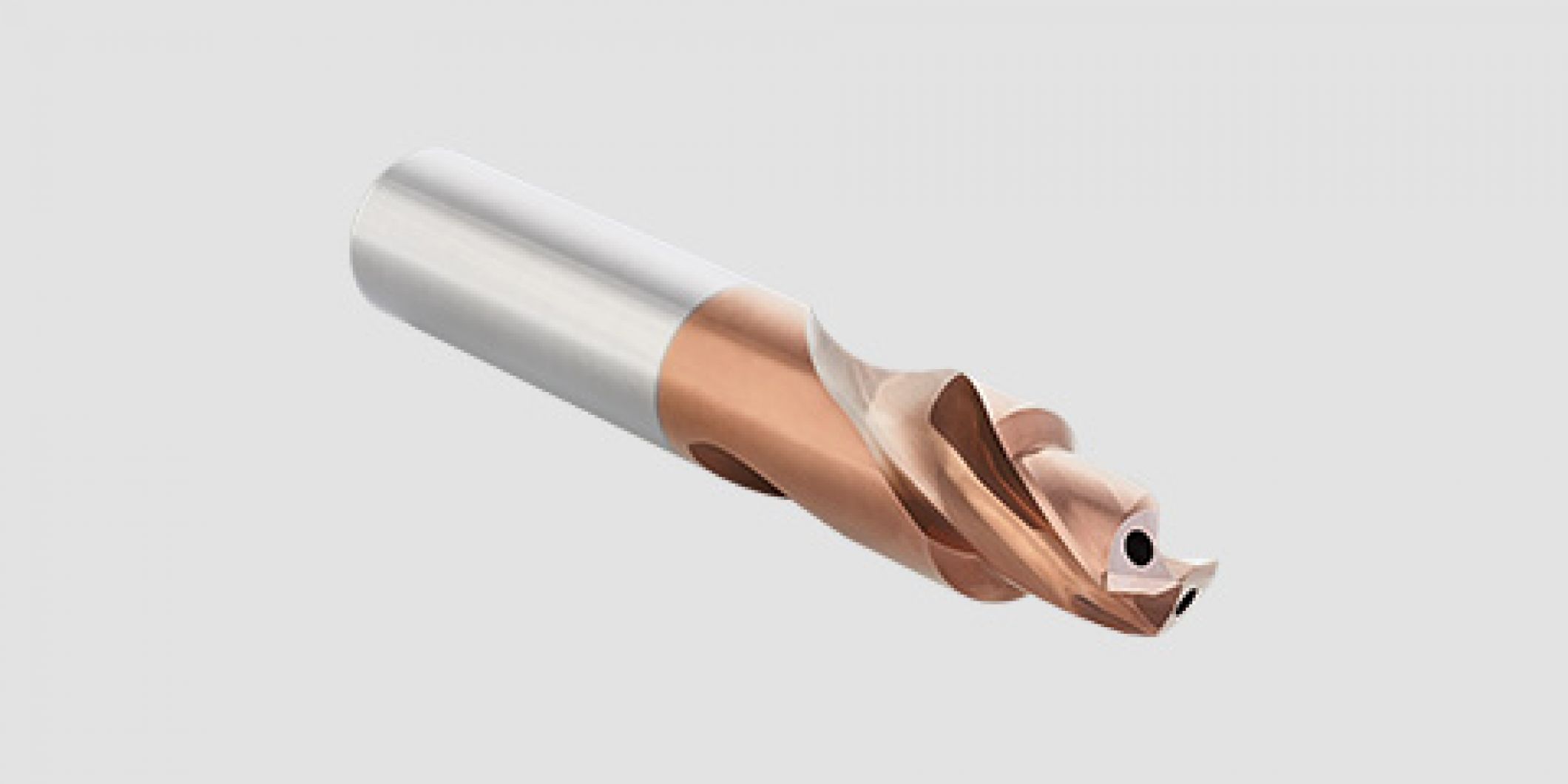

TX special

Highly efficient, application-specific special drills

Highly efficient, application-specific special drills which contribute to a significant optimization of processes and to the reduction of machining times.

Advantages high-performance drills

Solid carbide high-precision tools

For double feed rate with low cutting force.

Optimization and rationalization

By combining machining processes thanks to component-specific step tools.

Pre-machining with this high-performance drill

Is one of the success factors for optimum drilling results in combination with URMA high-performance reamers.

Special and step tools

Top Alu

FOR EFFICIENT ALUMINUM MACHINING

- Specially designed cutting geometry

- High feed rates and cutting speeds

- Innovative design of the flute profile enables short chip formation

- The strong drill back stabilizes the tool and significantly increases rigidity

- Ideal in pre-cast aluminum die cast parts

- Drilling into solid materials and with high positional accuracy

- Double feed rates compared to competitor drills

- Drilling into solid materials and with high positional accuracy

Top Cast T

FOR ALL CASTING MATERIALS through bores

Specially matched corner chamfers influence the chip shape and extend the main cutting edge accordingly.

- Improved stability and chip removal

- Smooth drill hole exit avoids flaking out

- Facet ground in connection with an innovative point thinning for excellent centering qualities and straightness accuracy

- Feed forces reduced by up to 30 %

- Double feed rates and shorter machining times

- Available as special tool and combined with various step geometries

Top Inox

FOR STAINLESS AND HIGH-ALLOYED, TOUGH STEEL

Efficient and economical machining of high-alloy and tough steels in mass production.

- Facet point with a specially developed point thinning

- Very sharp cutting edge with special cutting edge preparation

- Extremely small chisel edge reduces feed forces by up to 40%

- Can easily drill into tough material

- High positioning accuracy

- Excellent cylindricity and straightness

- Available as special tool and combined with various step geometries

Top Cast B

FOR ALL CASTING MATERIALS Blind Holes

Due to weight reduction in automotive engineering, material is saved. In the case of blind holes on cast housings, there is hardly any room for long gates.

- High feed rates even for short cuts

- Corner radii with an innovative cutting edge preparation

- Tried-and-tested point geometry together with innovative point thinning

- Nwly developed cutting edge stabilization enables extended tool life

- Reduced feed forces of up to 30%

- Available as special tool and combined with various step geometries