From 3D-printed raw part to high-quality product

From 3D-printed raw part to high-quality product

With the post-processing systems from DyeMansion, URMA is expanding its range of machines for additive manufacturing. The print-to-product workflow combines industry-leading technology with the widest range of color and finishing options on the market.

The print-to-product workflow

Our print-to-product workflow combines industry-leading technology with the widest range of color and finishing options on the market. Our mature Industry 4.0 systems can be seamlessly integrated into existing production processes. Learn all about Cleaning, Cleaning & Surfacing, Surfacing and Coloring.

Cleaning

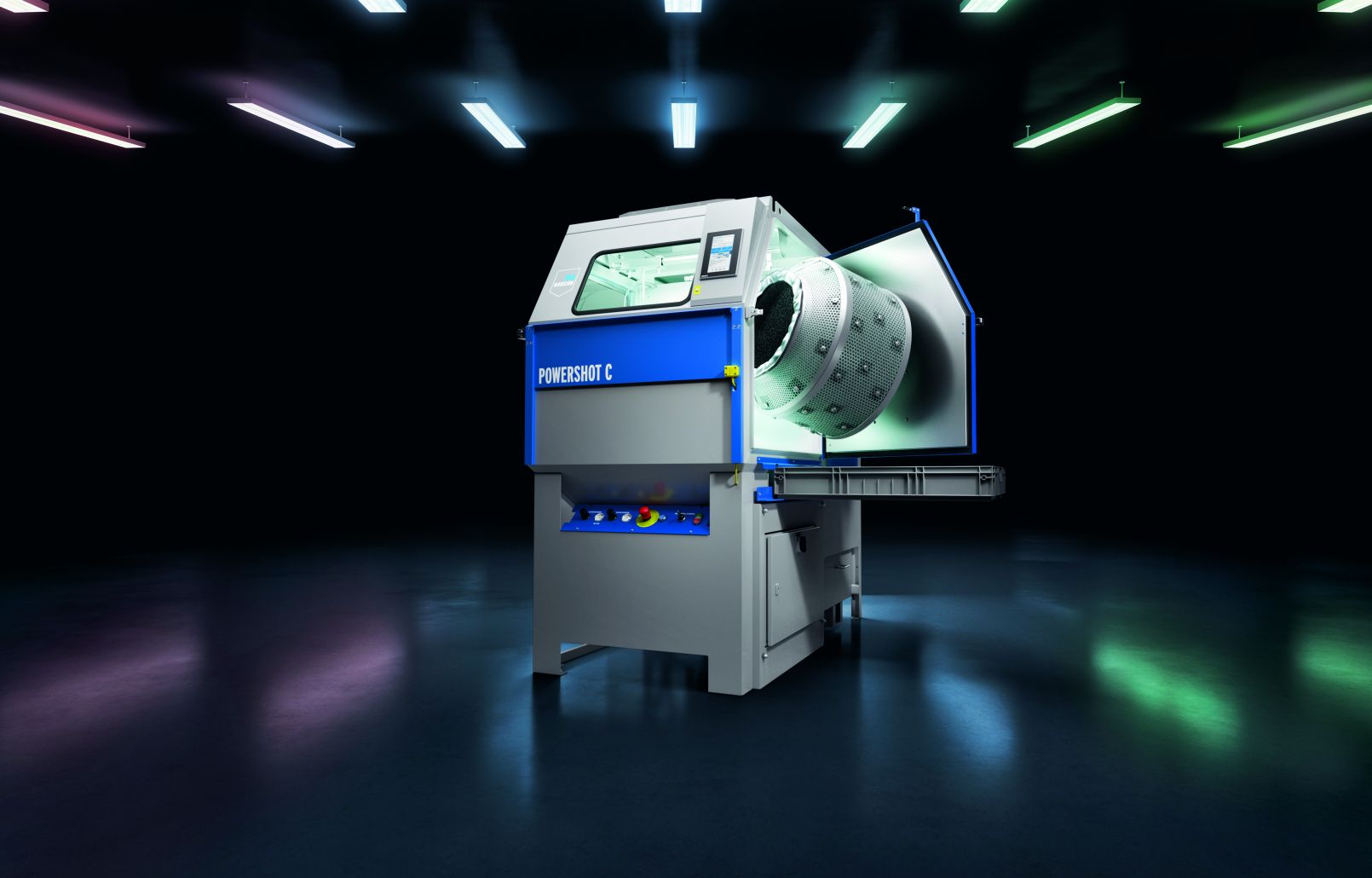

Clean additive manufactured parts with ease using the Powershot C from DyeMansion

Increase your production capacity

With the proprietary PolyShot Cleaning (PSC), a medium-sized build area can be depowdered in just ten minutes. The time you need for parts cleaning, as well as production personnel, can be significantly reduced. This increases your efficiency. By investing in automated depowdering with the Powershot C, up to four manual blasting systems can be replaced. PolyShot Cleaning is compatible with all common powder bed technologies and delivers residue-free parts for brilliant colors.

Surface treatment with intelligent hardware cabinet

The blasting cabinet of the DyeMansion Powershot C is equipped with a rotating basket and lined with stainless steel. Different blasting nozzles and ionization ensure reproducible results. A basket with soft, replaceable lining protects the parts from damage during the process. Two simultaneously operating blasting nozzles are arranged perpendicular to the rotating basket and the parts it contains. This configuration guarantees efficient powder removal.

High operating comfort

Experience a new level of process control via touch screen and integrated control panel. The pre-installed programs of the Powershot C are operated via a user-friendly interface. Individual programs can be easily configured and saved. The user-centered design makes everything easily accessible and safe to use. Continuous monitoring enables an efficient and reproducible process.

Powershot C

The Powershot C promises you automated depowdering, gentle surface treatment and a high level of operating convenience.

Powershot X

One solution for everything you need. You can use the Powershot X for either PolyShot Cleaning or PolyShot Surfacing, or you can use the unique combined PolyShot Cleaning & Surfacing process.

Get your free white paper now!

Automated, gentle & efficient

Using the DyeMansion Powershot C, up to 75% of an EOS P396 or HP Jet Fusion 4200 job can be cleaned in ten minutes. During the same period, significantly fewer parts can be cleaned manually.

Cleaning & Surfacing

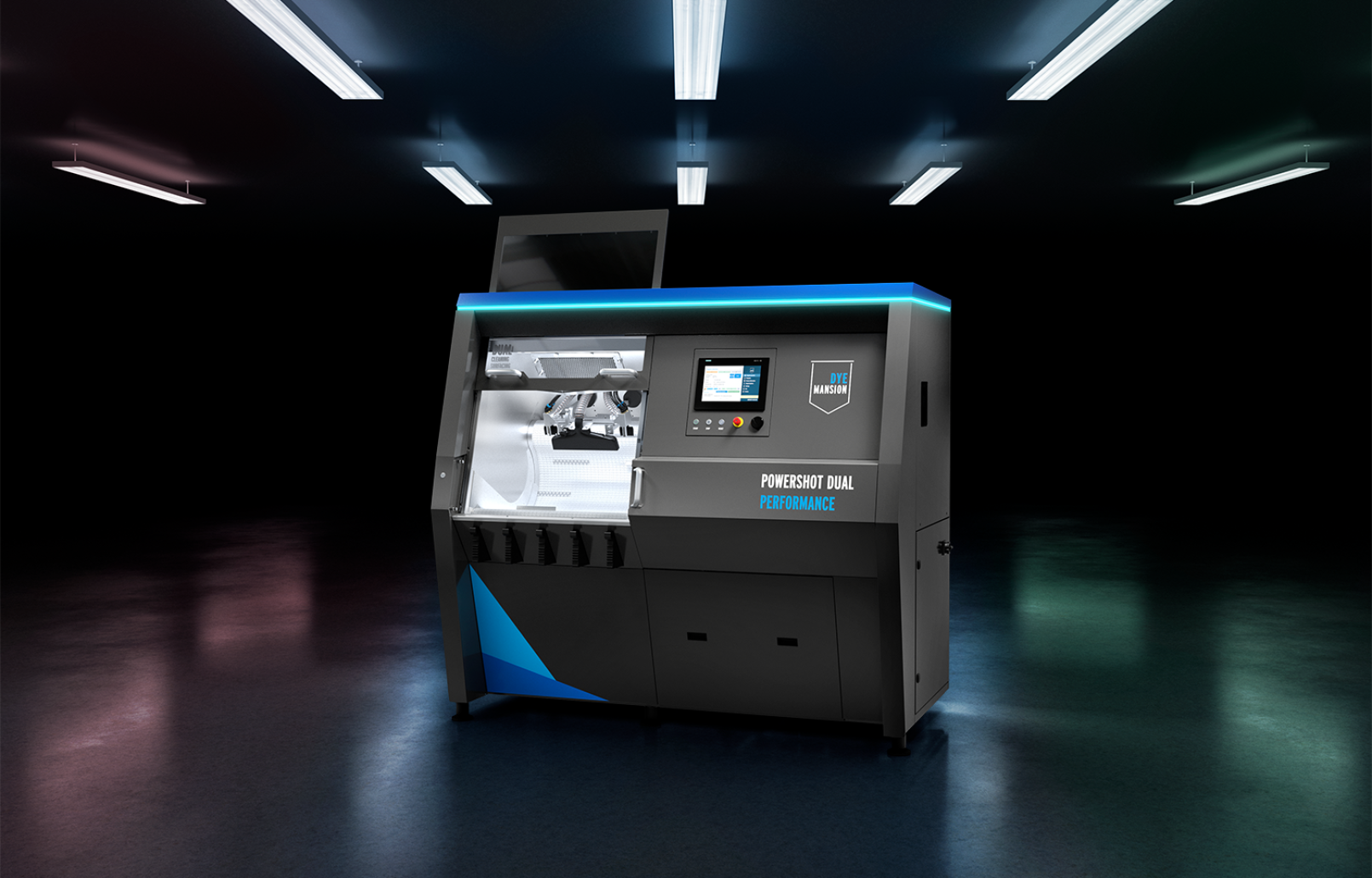

Optimize the quality of your 3D components with the Powershot Dual Performance from DyeMansion – for effortless cleaning & surface treatment.

With a short turnaround time and a full-size build capacity, the Powershot Performance Series is more efficient than any other system available. Complemented by DyeMansion's proprietary cleaning and surfacing processes, these systems are designed for high-volume production.

Powershot Dual Performance

Increase your production output – maximum efficiency with the smallest footprint required..

Boltenstern – the first premium jewelry manufacturer that produces 3D-printed collections

Surfacing

DyeMansion surfacing technologies – 3D printing surface optimization

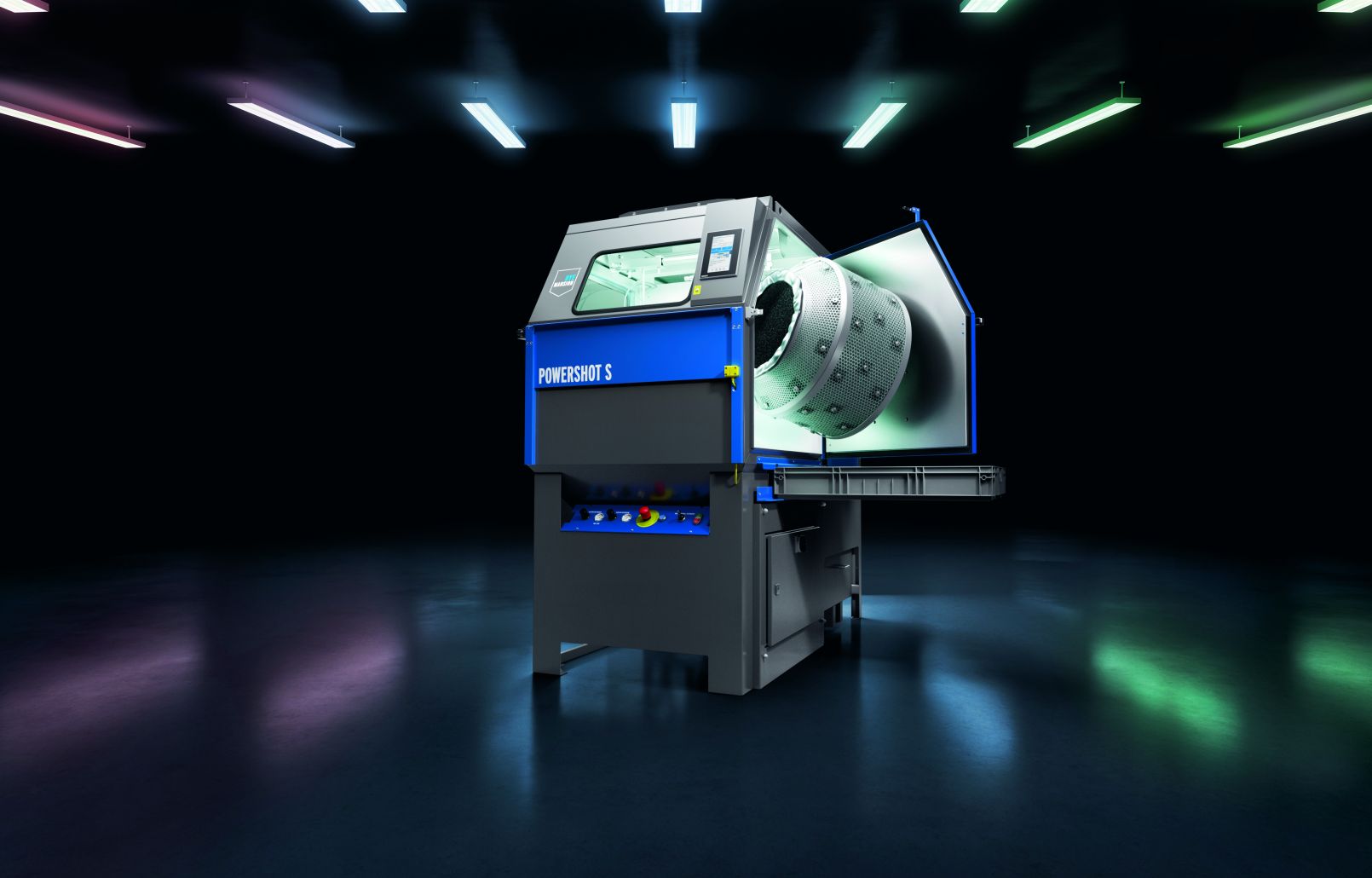

With DyeMansion, we offer a variety of surfacing technologies to optimize the post-processing of 3D-printed objects. These include PolyShot Surfacing (PSS) with Powershot S and VaporFuse Surfacing (VFS) with Powerfuse S and Powerfuse S PP.

Powershot S

Powershot S is an automated solution for post-processing PA12 or PA11 materials. The surface of the object is cleaned with a special jet to remove powder or dust residues. The advantage is that Powershot S works quickly and effectively, saving time and money on post-processing.

Powerfuse S

Powerfuse S is an automated solution specifically designed for finishing parts made of materials such as PA, TPU and more. It uses a combination of heat and pressure to melt and smoothly polish the surface of the object. The advantage is that Powerfuse S produces a more uniform surface that has a higher haptic and professional look, which is particularly beneficial for use in product development and prototyping.

Powerfuse S PP

Powerfuse S PP is a special version of Powerfuse S designed for the finishing of PP parts. PP is a thermoplastic polymer that, due to its properties, requires special finishing to achieve a smooth and uniform surface. The advantage of Powerfuse S PP is that it offers a fast and effective solution for the post-processing of PP parts, saving time and costs.

Coloring

DyeMansion's color world – brilliant colors and individual surface finishing for 3D-printed objects

World's largest color database

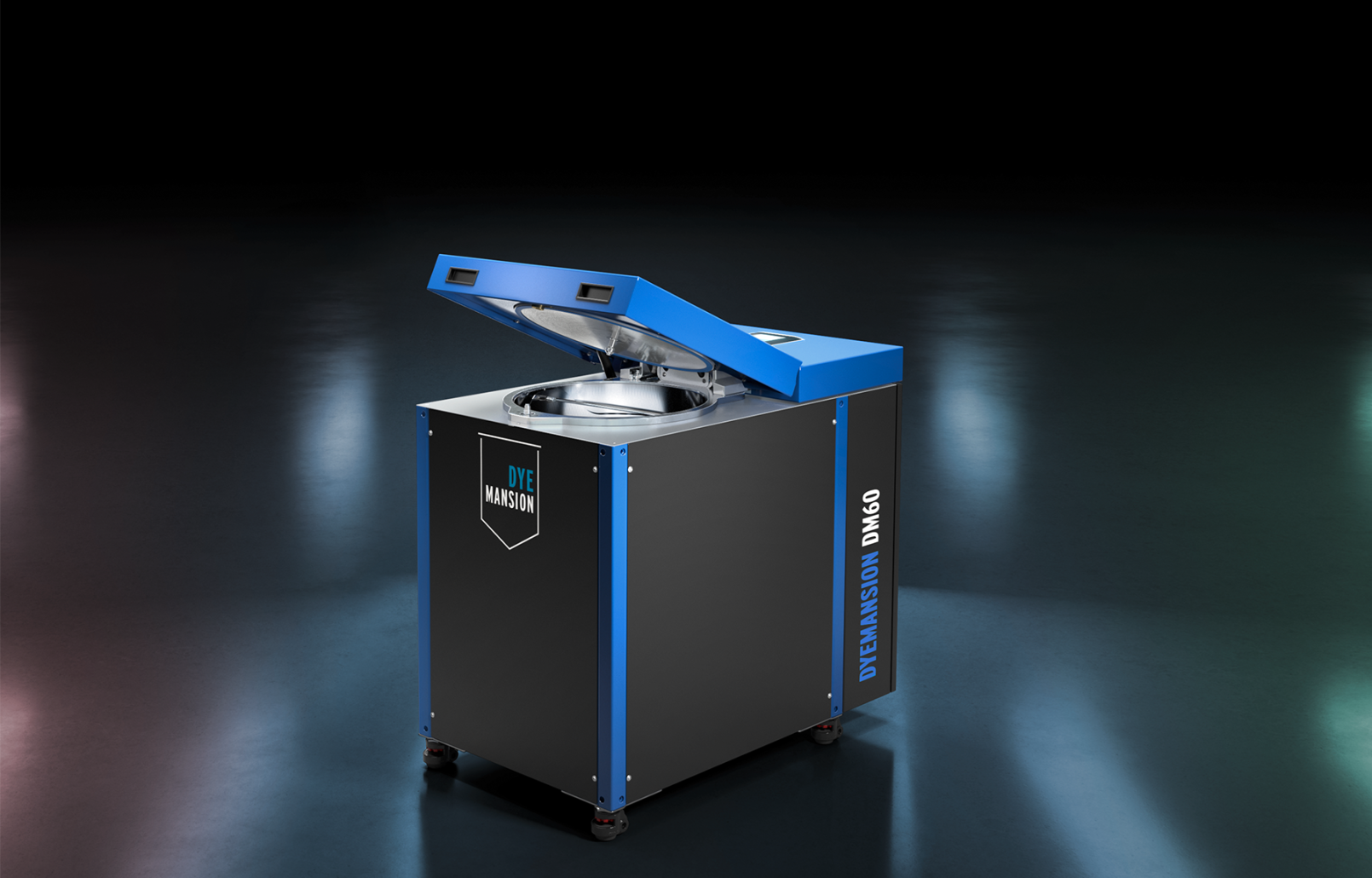

The innovative DeepDye Coloring (DDC) technology sets no limits to your color preferences. In addition to the more than 170 standard and RAL colors, which are ready to use at any time without additional development costs and waiting times, custom tones can be made for you – from corporate colors to seasonal trend colors to individual skin tones. The integrated and fully automatic cleaning program of the DM60 allows flexible use as well as fast color change.

Exact ink formulation

Coloring 3D-printed plastic parts has long been a manual, uncontrollable process. DyeMansion takes this process off your hands and provides you with microgram-precise color formulations worldwide. This enables a process flow suitable for industrial use, which could not be easier for the user and can be reproduced at will. The strength here lies in our color cartridges, which are made according to the base material, finish and desired color. Our cartridges are available in four sizes, depending on the volume of your components, and are equipped with an RFID chip that aptly transfers all process parameters to the DM60 QM.

ISO-certified colors

The requirements for additively manufactured products are constantly increasing. With the expanded ColorsX color line, DyeMansion is targeting industry-specific requirements and continuously developing DeepDye Coloring (DDC) technology.

DM 60

The leading coloring solution for industrial 3D printing: from the standardized database to individual formulations.

Colors

Bringing products to life! Discover the largest color database for 3D-printed parts on the market with DyeMansion.

Add-On Solutions

DM60 reservoir for efficient black coloration in large quantities and DyeMansion ROS for constant water quality.

URMA is an expert in 3D printing – from initial consultation to quality inspection

Additive manufacturing enables a high degree of flexibility, effectiveness, automation and process safety, as well as the traceability of production. To ensure successful industrialization, the entire process chain from design, optimization, production, post-processing – and all the way to quality inspection – must be taken into account.