Flexible and economical production of high-quality components

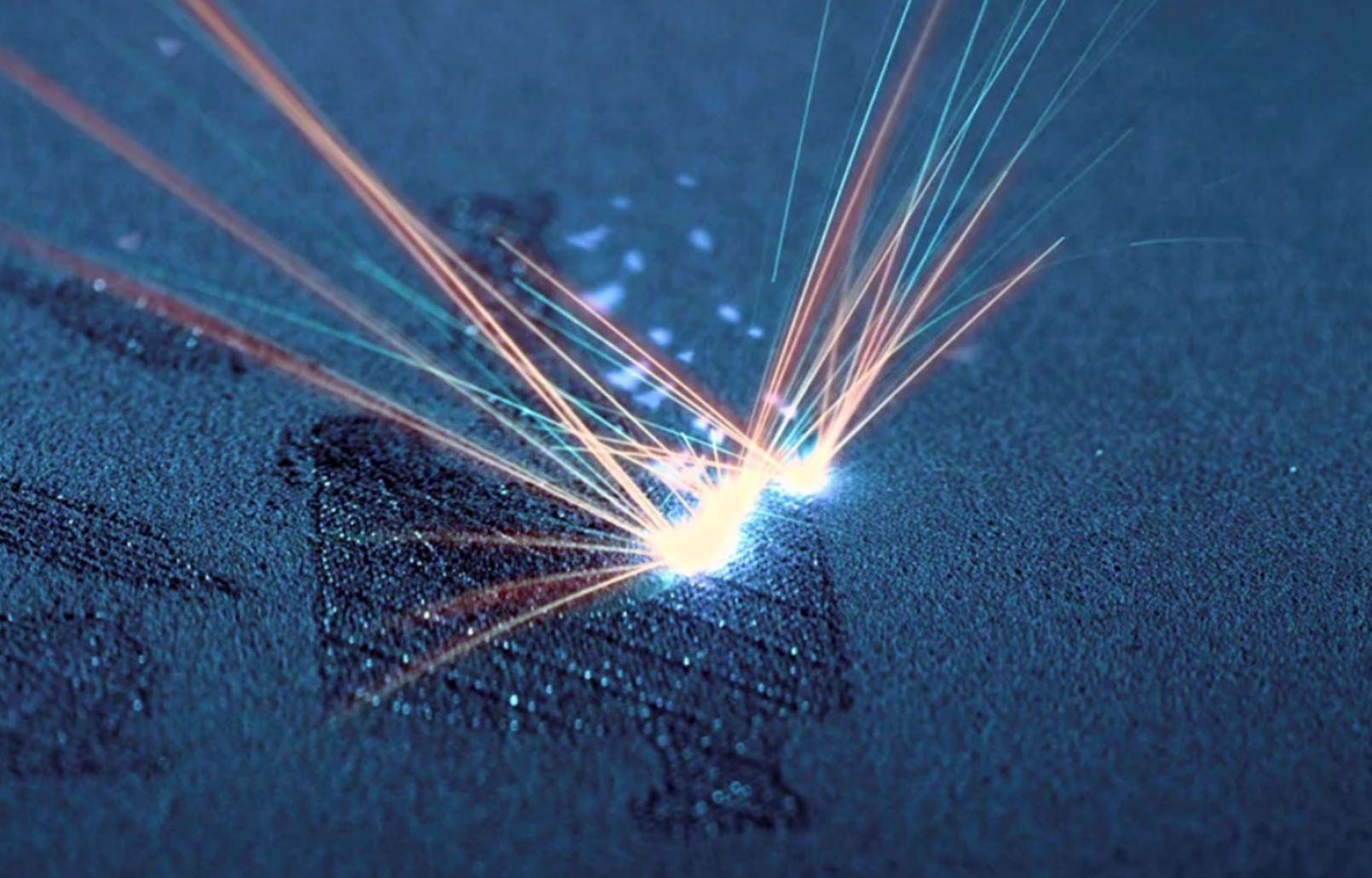

Metal 3D printers – Reliable production for a wide range of customers worldwide!

Reliable production for many customers worldwide! Are you looking for the right metal 3D printer for the industrial production of high-quality components? EOS offers additive manufacturing systems with certified DMLS quality, ideally suited to the individual requirements of your production.

With its broad material portfolio, the EOS M 290 offers the perfect package for additive manufacturing involving high-quality metal components. This established medium-sized 3D printing system delivers an impressive performance with its sophisticated quality management system.

Pre-processing and design:

Create and import print data

In order to create a digital template, the data must first be prepared. Such a 3D model can be designed using a CAD program, or digitized using a 3D scanner. This is followed by checking the CAD model, correct positioning on the respective surface and adding support structures.

3D scan

Easily measure objects with the portable “Handy Scan 3D” from Creaform, in order to obtain the component’s CAD data, or subject components to a subsequent quality check by scanning the finished workpiece.

Software

With the Materialise Magics software platform or Hexagon AM-Studio, you are ideally equipped to manage and automate labor-intensive tasks and scale processes – irrespective of the 3D printing technologies or machines.

EOS-Systems

EOS Plans offer a flat rate of validated and ready-to-use processes, including powerful hatching algorithms for first-time-right exposure, as well as an automatic in-situ process control for reduced supports and increased productivity.

EOS M 290 Series

Highly productive, modular and established medium-sized 3D printing system with a very broad portfolio of materials for the additive manufacturing of high-quality metal components - in series or as prototypes.

EOS M 300 Series

Digital additive manufacturing for the production of high-quality metal parts. Developed for industrial production, the EOS M 300 series offers a high degree of flexibility with up to 10x higher productivity.

EOS M 400 Series

Thanks to a build volume of 400 x 400 x 400 mm and a 1000-watt laser power, the EOS M 400 enables the production of high-quality metal parts on an industrial scale - directly from CAD data and without tools.

Materials

EOS offers a comprehensive portfolio of advanced metal materials (3D printing material) specifically developed for additive manufacturing involving EOS DMLS technology. The portfolio comprises in excess of 28 alloys and 75 process parameters: aluminum, stainless steel, cobalt, chromium, nickel-based, titanium and tool steel alloys, as well as refractory and precious metals.

Special solutions from AMCM

AMCM is an EOS company, and offers customized 3D metal printers. AMCM modifies (and extends) existing EOS systems, in order to meet customer-specific requirements – such as adapting the laser or construction volume – if you have any special requests, AMCM is the right partner for you!

Post-Processing:

Post-processing and quality assurance

Depending on the printing process and component requirements, the amount of post-processing required for 3D-printed parts varies greatly. URMA provides you with various solutions and machines for the CNC machining of components. Quality control, for example, also plays an important role in post-processing.

De-powdering with Solukon

Rotations, as well as targeted vibration excitation, ensure that the powder can flow out of even the finest inner channels. For reactive materials, such as aluminum or titanium, the systems can also be inertized. The Solukon depowdering systems are compatible with all printers of the metal powder bed process.

CNC machining: HAAS

URMA provides a comprehensive selection of vertical and horizontal machining centers, CNC lathes, turning and indexing tables, as well as 5-axis machining centers from HAAS. In addition to this range, URMA also offers machining centers for mold making, machines for tool and fixture construction and milling machines based on a portal design.

CNC machining: Zorn

The Zorn microone is a compact and small precision machining center for milling, drilling and grinding miniature parts. The solid granite foundation absorbs the smallest movements, thereby guaranteeing maximum precision and stability. In addition, microone can be expanded with automatic cells.

URMA – ein Partner für alles

URMA is an expert in 3D printing. From initial consultation to quality inspection, we support you in the introduction or expansion of your additive manufacturing. You, too, can benefit from the comprehensive URMA services:

- Consulting

- Services

- Training & Support

- Funding

- System technologies

- Showroom

- Network

- Webshop