Perfection in turning and milling

High-tech machine tools for high-quality and customized automated solutions in metalworking

With the EMCO machine portfolio, URMA has expanded its CNC range for high-precision and productive metalworking and offers the right application for all requirements.

Flexible, multifunctional and efficient - EMCO CNC machines for turning and milling applications

EMCO offers a comprehensive portfolio of turning and milling machines for the high-precision machining of various metals. The range of machines extends from conventional turning and milling machines to CNC turning centers, vertical machining centers and fully automated production cells. Thanks to the individualization of the CNC machines and the automation options, there are no limits to the applications.

Machining in the watchmaking and medical industries

The precise machining of large and complex workpieces requires a high degree of flexibility in the watchmaking and medical industries. The machining of components made of high-alloy steels, titanium alloys or ceramic materials also places special demands on the machine tool.

EMCO CNC machines offer versatility, digital options for automation and a team of experts for process optimization and technology consulting for a comprehensive analysis, production consulting and the selection of suitable machines to meet your quality standards and production goals.

Your advantages

User-friendly operation

Control options from Heidenhain, Siemens or Fanuc

Software-controlled process monitoring

Optional EMCONNECT Digital Services for automatic notifications and remote maintenance options

Automation options

Robotics seamlessly integrated into the control system and much more

Individual configuration options

Customized software and automation solutions for your individual application

From Europe for Europe

EMCO develops and produces in Europe for the highest quality requirements and flexibility in the event of market changes

Technological advantage

EMCO has been producing lathes since 1947 and is one of the world market leaders in CNC lathes and milling machines

Maxxturn

With its extensive equipment, the Maxxturn series offers everything for complex and precise turning and milling operations with a rigid Y-axis and large traverse path for unlimited machining options for chuck, shaft and bar parts.

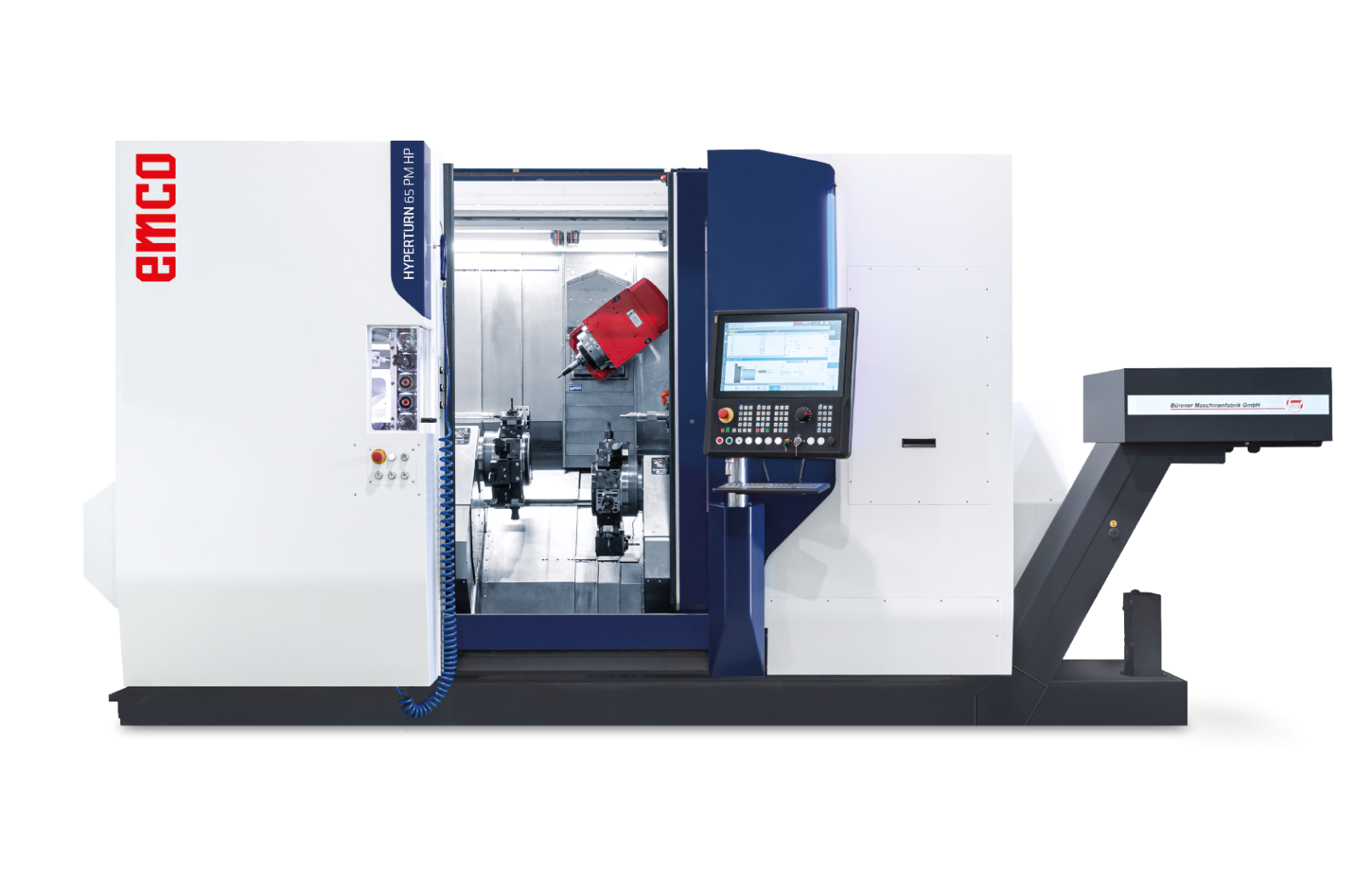

Hyperturn

The Hyperturn line is the combination of modern turning and milling technology for the complete machining of complex workpieces: This CNC series is characterized by its ability to perform turning and milling machining tasks in a single machine.

Hyperturn Powermill high performance

Turning and milling in one: The Hyperturn Powermill high performance turning and milling center has a fully-fledged milling spindle for complex milling work.

Milling

EMCO milling CNC machines are characterized by their precision, versatility, user-friendliness and innovative technology. With a strong focus on quality and performance, they are ideal for manufacturing companies that require high-quality machining results and reliable performance - from prototyping to series production.

Emcomill

Compact technology for maximum efficiency: The Emcomill series features powerful, high-quality milling machines with traveling column.

UMill

The compact universal milling machines are ideally designed for 5-axis machining operations such as milling, drilling, tapping and turning in a single set-up. UMill has roller guides and glass scales in all linear axes for maximum accuracy.

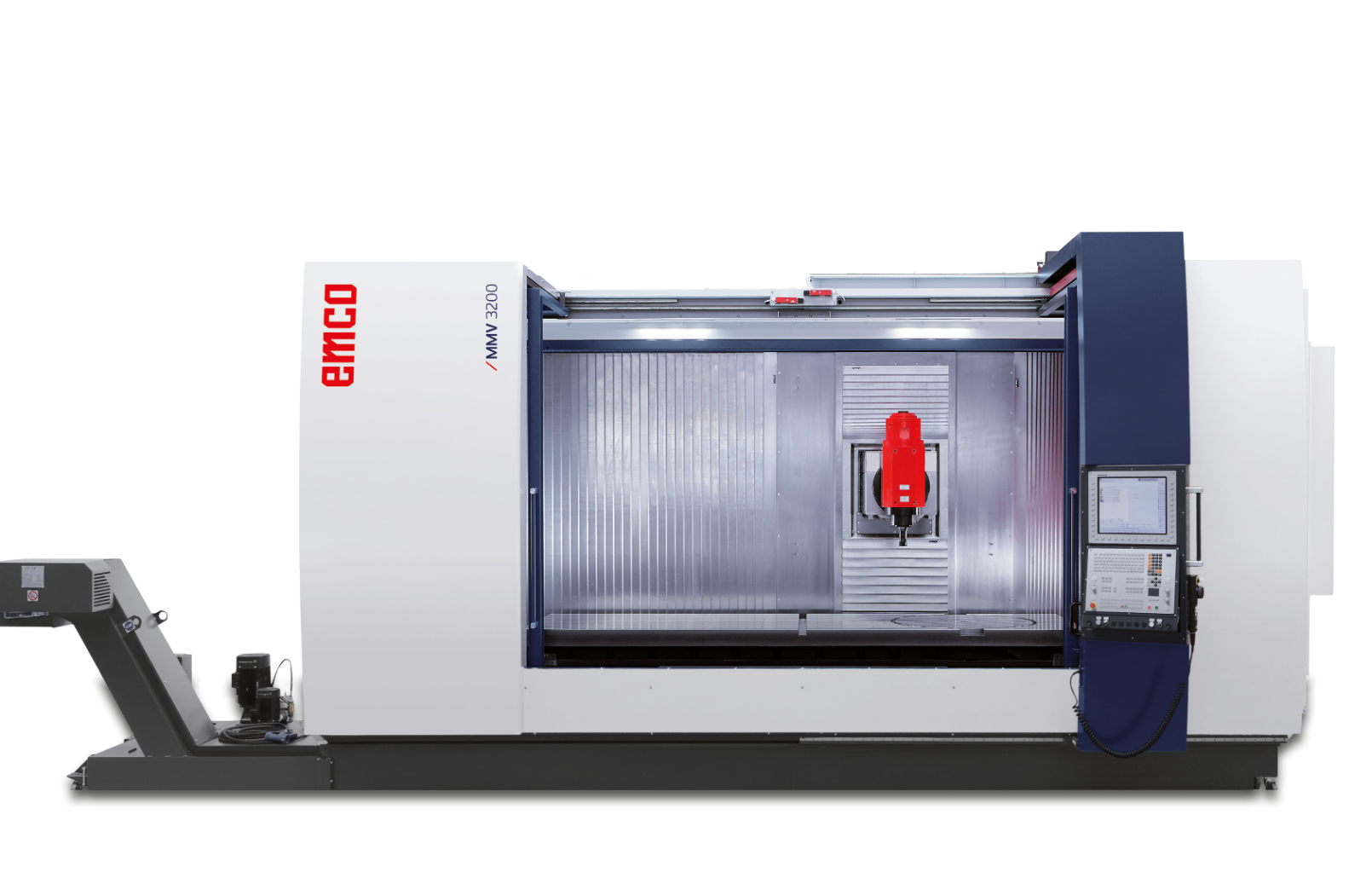

MMV

The machining centers of the MMV series can be used for the complete machining of very large and heavy parts in a single clamping operation (travel X = 6,200 mm, max. 8,000 kg). Even at high cutting performance, they achieve maximum accuracy and surface quality.

Emcomat turning

The conventional EMCO turning centers are indispensable for high-precision one-off production and repairs. They have infinitely variable speed control and are equipped with a digital display.

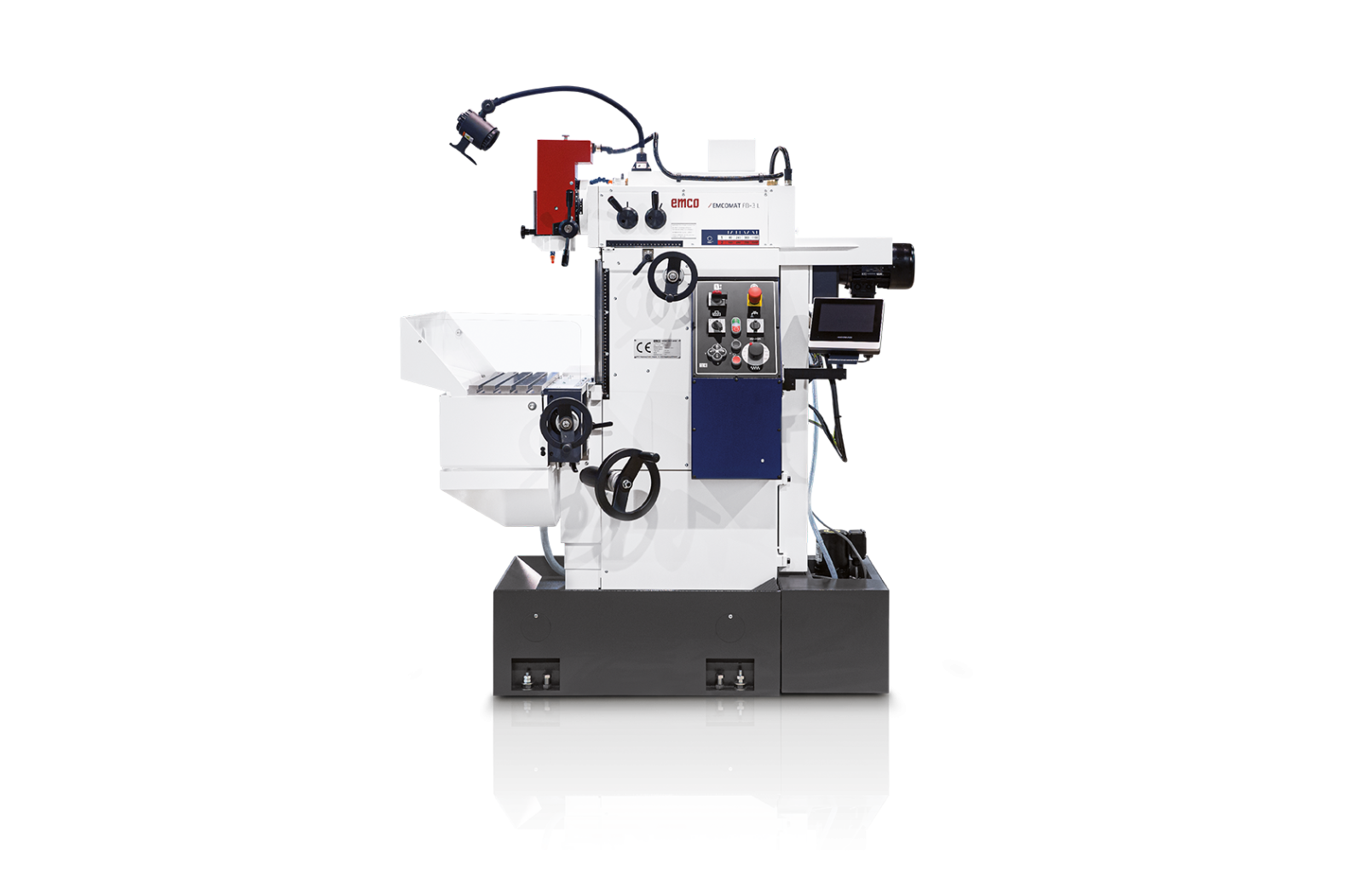

Emcomat Milling

The universal milling machines are equipped with a swivel-mounted vertical milling head and offer a wide range of options. They are ideal for small series production with the highest demands on accuracy and flexibility.

Flexible and individual: automation solutions from EMCO

By integrating functional standard solutions and highly flexible elements from innovative cooperation partners, EMCO provides customized concepts that meet your individual requirements and offer you maximum efficiency and reliability.

From compact standard automation systems to universal loading and unloading equipment for preformed blanks of all kinds or versatile gripper and handling systems: You receive standardized and flexible solutions for the automation of your machines for various tasks such as

- Robot-assisted loading systems

- Pallet changing systems

- Tool changing systems

- CNC controls with automation functions

- Software-supported process monitoring and control

- and many more

URMA service offer

In addition to sales, we offer excellent service and comprehensive application support. Our EMCO service team consists of factory-trained personnel who are qualified to maintain and repair your EMCO machine. As a direct seller, we operate an extensive spare parts warehouse for fast deliveries.

Our service vehicles are also equipped with the most common parts to guarantee you the fastest possible service and reliable maintenance