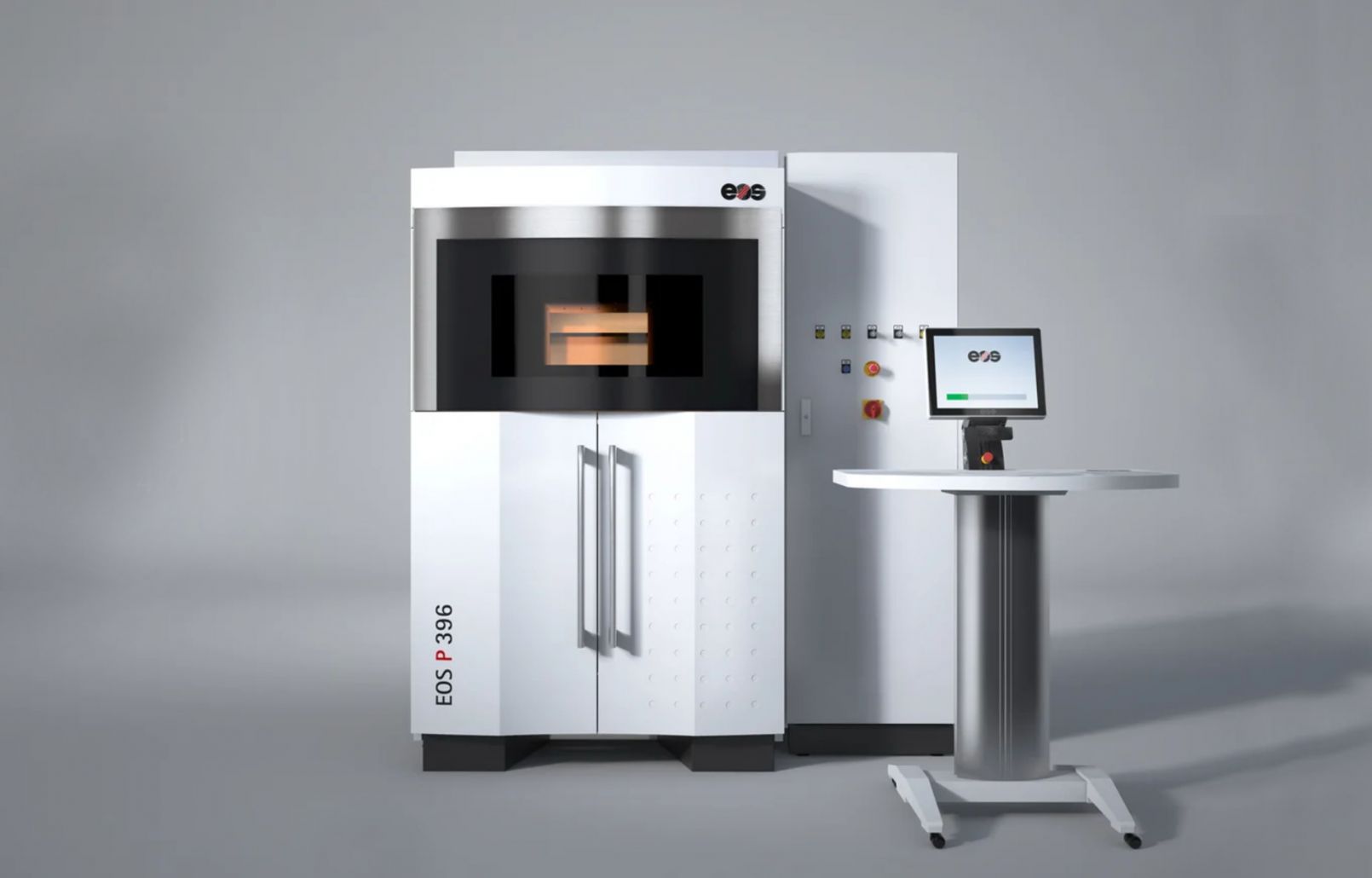

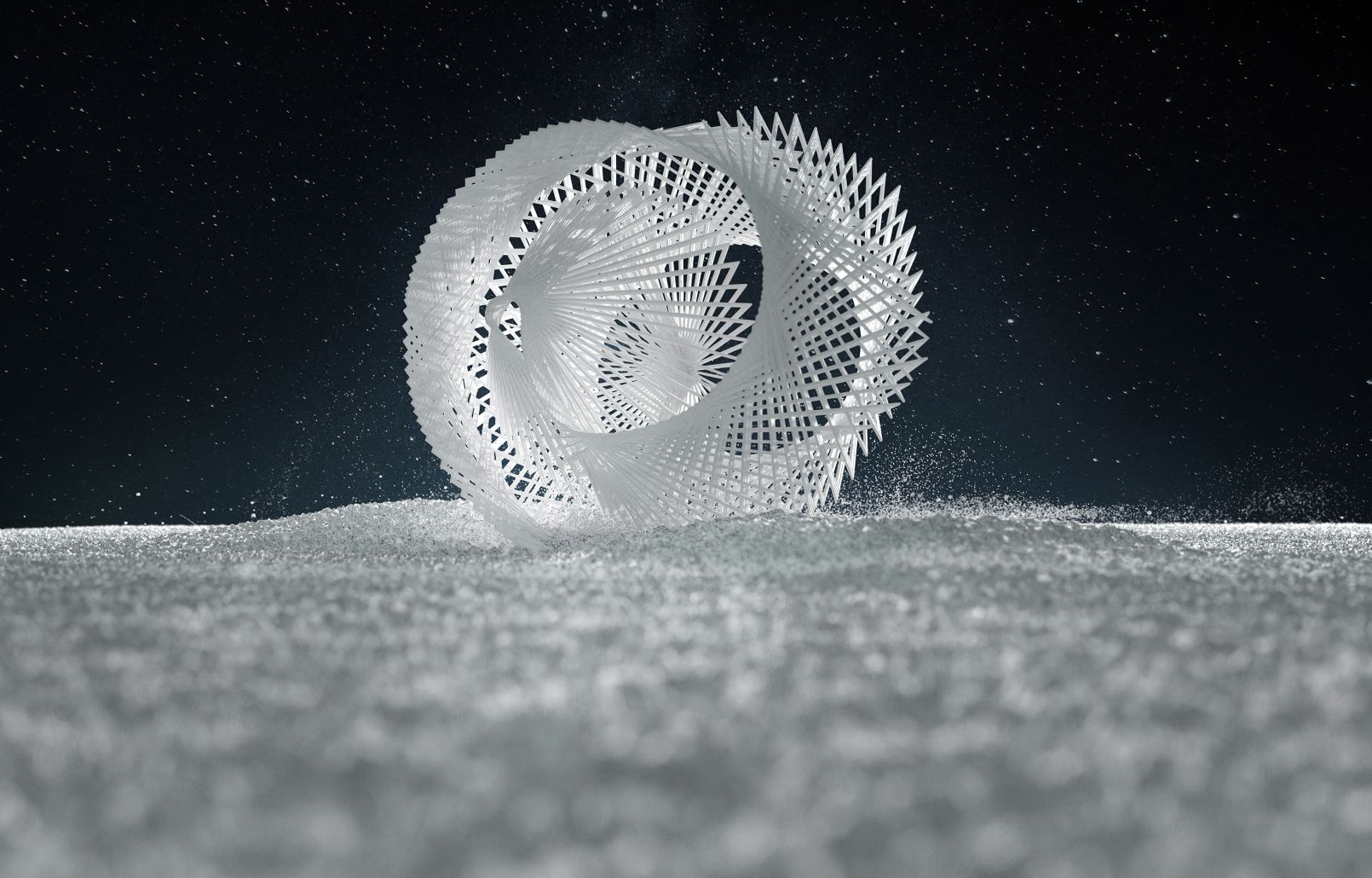

With 30 years of experience in 3D printing for industrial applications, EOS has perfected the process of powder bed-based additive manufacturing involving plastics. EOS has mastered the interaction between 3D printing system, material and process for the production of components on an industrial scale. This technology establishes the basis for production results that meet the most diverse industrial requirements in terms of dimensional accuracy, surface quality and stability.

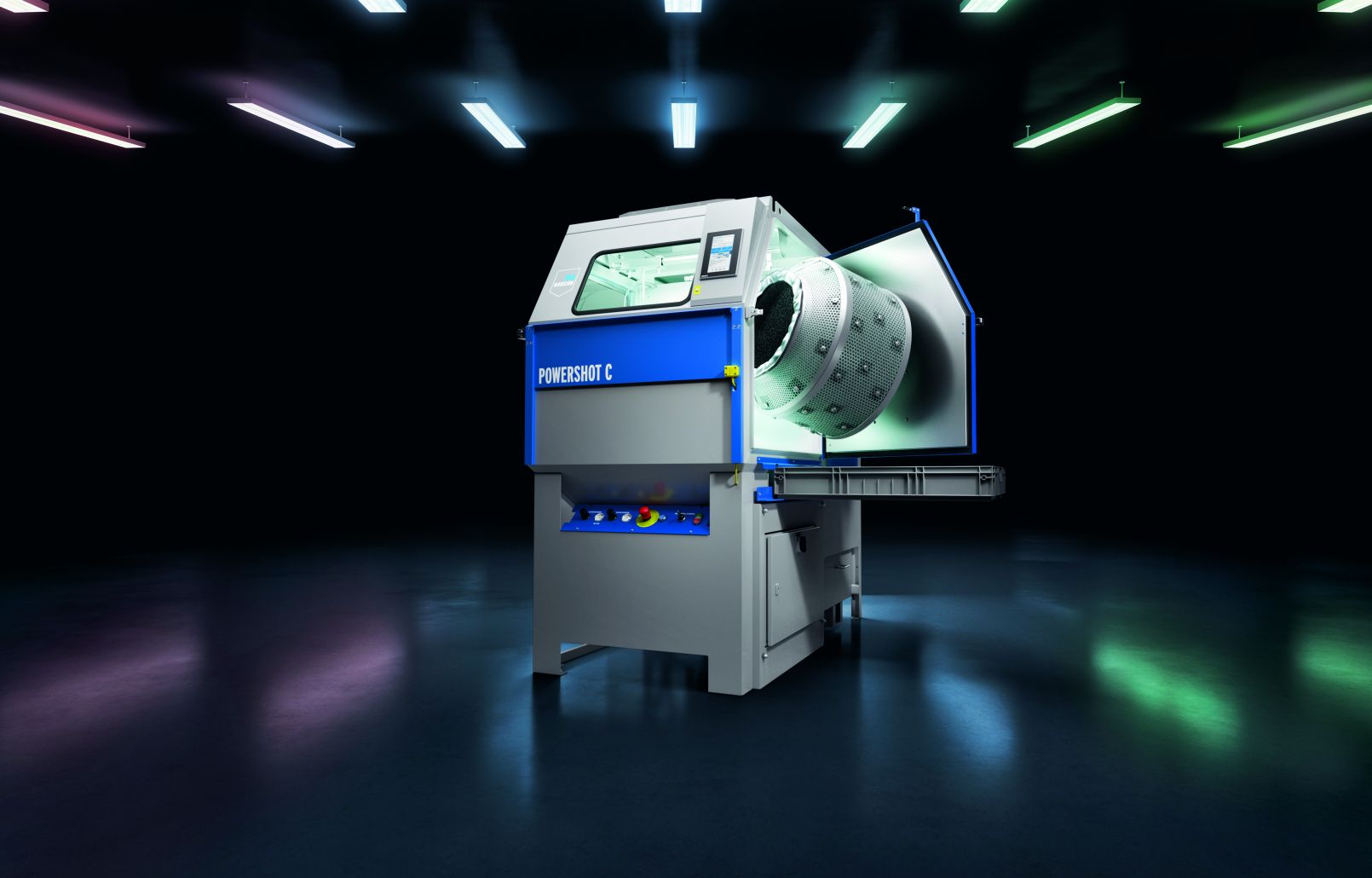

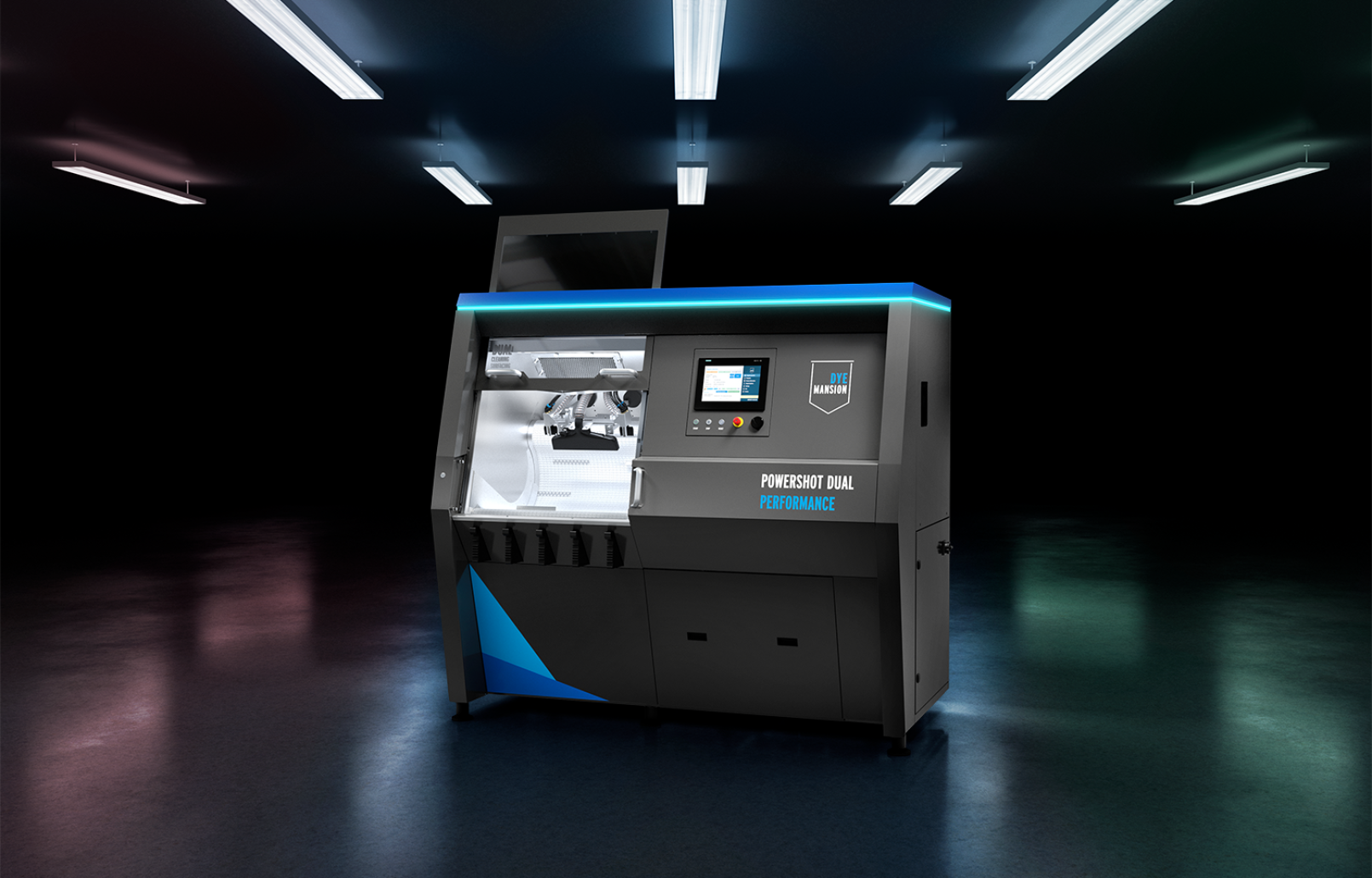

Since 2021, URMA has been the exclusive distributor in Switzerland of the extensive product portfolio for industrial 3D printing from EOS. As a user, you benefit from integrated production solutions. Be it stand-alone or as a supplement to your existing production environment: our efficient and integrable EOS solutions adapt to your individual production requirements.